ERSA Selective soldering systems

"Best in Class" Selective Soldering systems from the world market leader

Leading edge technology and modular design match the highest demands on flexibility and throughput while fitting in virtually every budget. Ersa, with its line of selective soldering systems VERSAFLOW, ECOCELL and ECOSELECT, offers optimal solutions to all requirements.

Highlights Selektive Soldering System

Ersa SMARTFLOW 2020

- Compact without compromises

- Modern process visualisation with ERSAsoft 5

- Convenient PC control with swiveling 24'' touch-screen

- Ersa CAD-Assistent

- Use of Mini-Vario-Wave, Mini-Dip and area nozzles

- High ease of servicing

- Drop-Jet Fluxer with integrated monitoring

- Highest positioning accuracy and process

- All-over heating IR preheating lower/upper (scalable)

- Low energy and N2 consumption

See more about Smartflow 2020 on Ersa webstie

Highlights Selective Soldering System Ersa ECOSELECT 1

- Compact Batch-type system with small footprint

- Ersa CAD Software

- Up to 2 solder bath to increase throughput

- Use of mini-wave, mini-dip wave and area-soldering nozzle possible

- Maintenance free electromagnetic solder pump drive

- Drop-jet fluxer with integrated monitoring

- High positioning accuracy and process safety

- Lower, full-area IR preheater (scalable)

- Convection top side

- Low energy and N2 consumption

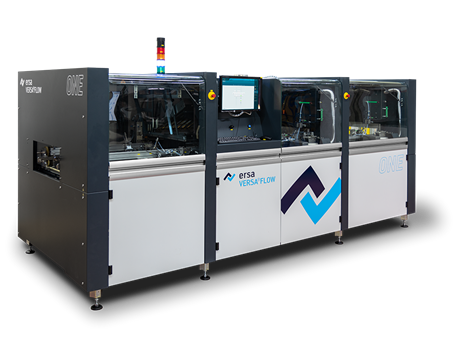

Your entry into the excellence class of Selective Soldering: Top quality with a compact footprint - the VERSAFLOW ONE is the new entry into the portfolio of Ersa VERSAFLOW inline selective soldering systems. The system combines proven Ersa DNA and customer-oriented option structure with high availability at extremely attractive acquisition as well as operating costs.

Highlights Selective Soldering System Ersa ECOSELECT 4

- Flexibly integrable soldering system: inline or batch operation

- VERSAFLOW 4 technology

- PCB size 508 x 508 mm

- Roller conveyor

- Up to two spray heads and flux tanks

- Powerconvection

- y/z variable dual solder pots

- Automatic nozzle activation

- Upgrade with independent flux module to a full inline machine

- Award-winning ERSASOFT 5 software

- VERSACAM – solder wave height measurement “on the fly”

Highlights Selective Soldering System VERSAFLOW 3/45

- High end selective soldering system to integrate into in-line manufacturing concepts

- Mini-wave soldering for high flexibility or multi-wave soldering for high volume applications

- Product change without loss in production time with the multi-wave process

- Parallel process through separation of fluxing, preheating and soldering cycle

- Use of up to 4 flux spray heads

- Flexible system configuration on account of modularity of the design

- Optional board examination systems VERSASCAN and VERSAEYE

- Ideal for linking to manual workstations or peripheral equipment

- Secure process control with monitoring of all relevant processes

- CAD-Assistant for offline programming

- Link for traceability systems for process control

See more about Versaflow 3/45 on Ersa website

Available also Ersa Versaflow 3/66 for bigger working area.

Highlights Selective Soldering System VERSAFLOW 4/55

- High end selective soldering system to integrate into in-line manufacturing concepts

- Mini-wave soldering for high flexibility or multi-wave soldering (in preparation) for high volume applications

- Product change without loss in production time with the multi-wave process (in preparation)

- Processable area 20″ x 20″

- Soldering module Y/Z variable

- Versacam for height measurement on the fly

- Versaflex soldering module X/Y/Z variable

- Power convection for optimal homogenous preheats

- Parallel process through separation of fluxing, preheating and soldering cycle

- Use of up to 4 flux spray heads

- Fluxer y-variable

- Flexible system configuration on account of modularity of the design

- Ideal for linking to manual workstations or peripheral equipment

- Secure process control with monitoring of all relevant processes

- CAD-Assistant for offline programming

- Link for traceability systems for process control

See more about Versaflow 4/55 on Ersa website

Revolutionary variety and flexibility in selective soldering

Tech-Highlights VERSAFLOW 4 XL

- Intelligent high-end selective soldering machine for inline production concepts

- Full modularity - suitable for every customer requirement

- Tripling of throughput with highest flexibility

- Intuitive operating concept

- Highest process reliability through proven control systems

Highlights Ersa CAD Assistent 3D:

- Unique off-line program preparation

- Intuitive programming with graphical and tabulated user interface

- Optimized cycle times through auto routing

- Avoidance of collisions through definition of exclusion areas

- 3D display for visual control

- Copying of program steps allows for time-saving program preparation for multiple-up panels

- Transparent display of points, tracks and exclusion areas facilitates program preparation of complex assemblies

- Handling up to 3 solder modules is possible

- Easy scaling of the assembly

The efficient creation of complex solder programs for Selective Soldering Systems is of central importance. As quickly as possible and without error, that is the maxim. With the Ersa CAD Assistant 3D the programming takes place offline, while the system itself is in operation! As such, the Ersa CAD Assistant 3D delivers excellent services: The possibility for off-line programming ensures the maximum uptime of the system.

At the same time, the software offers the comfortable possibility to quickly and easily create the desired solder program.